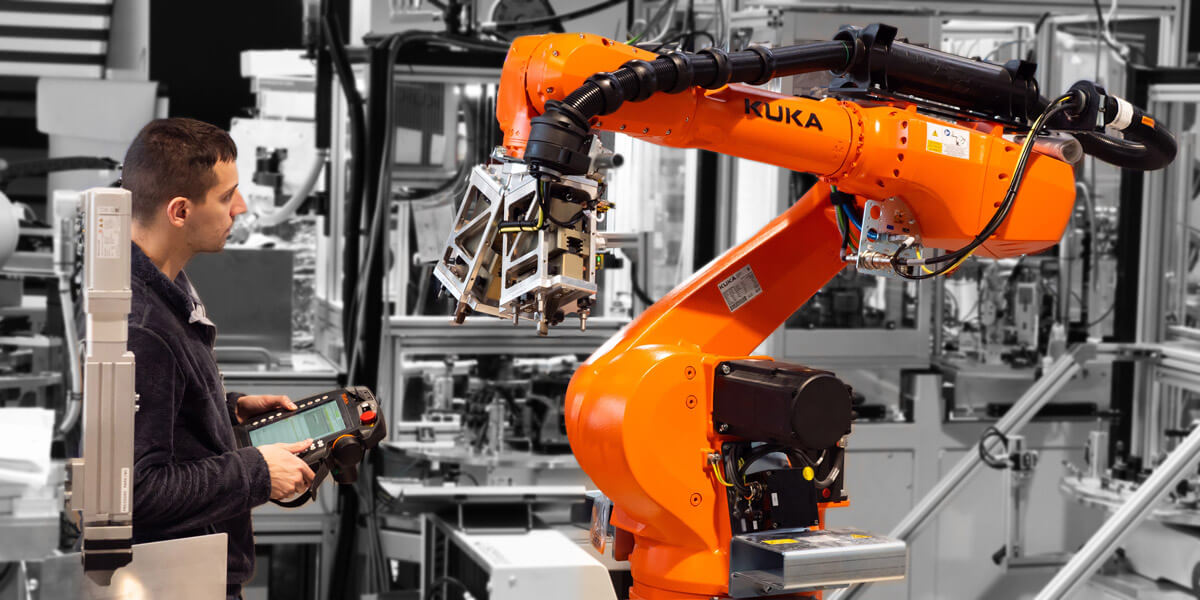

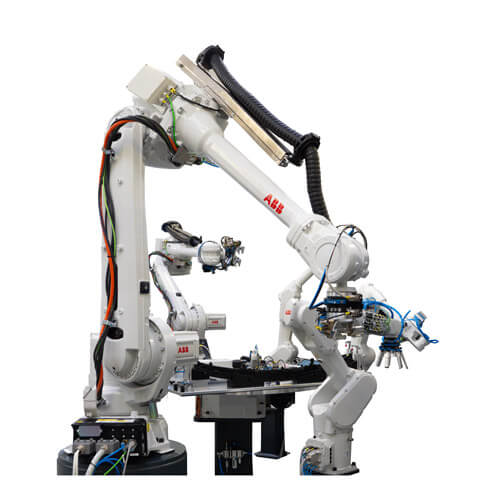

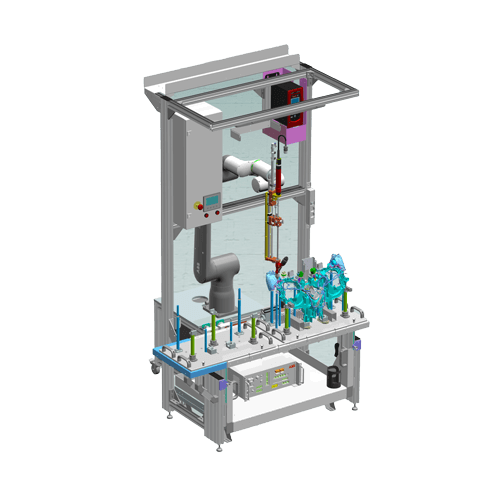

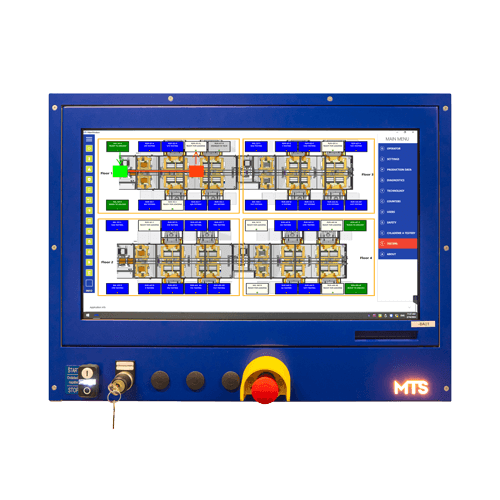

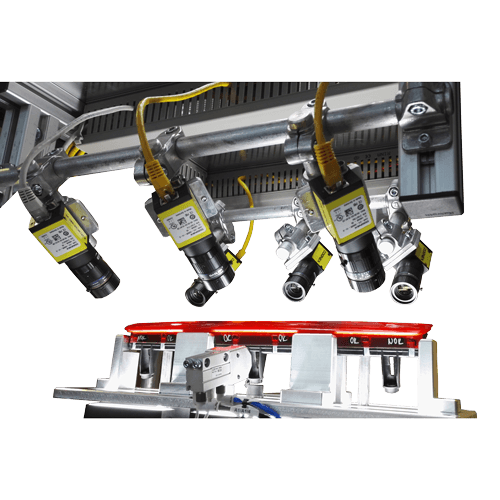

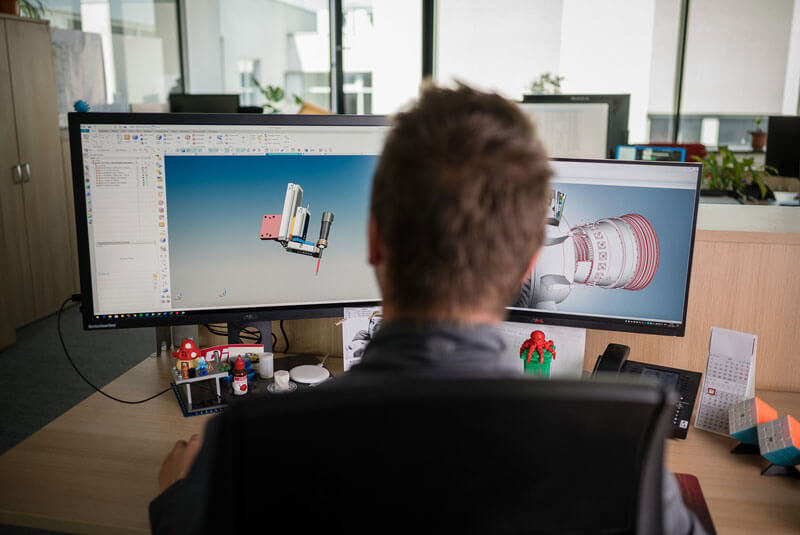

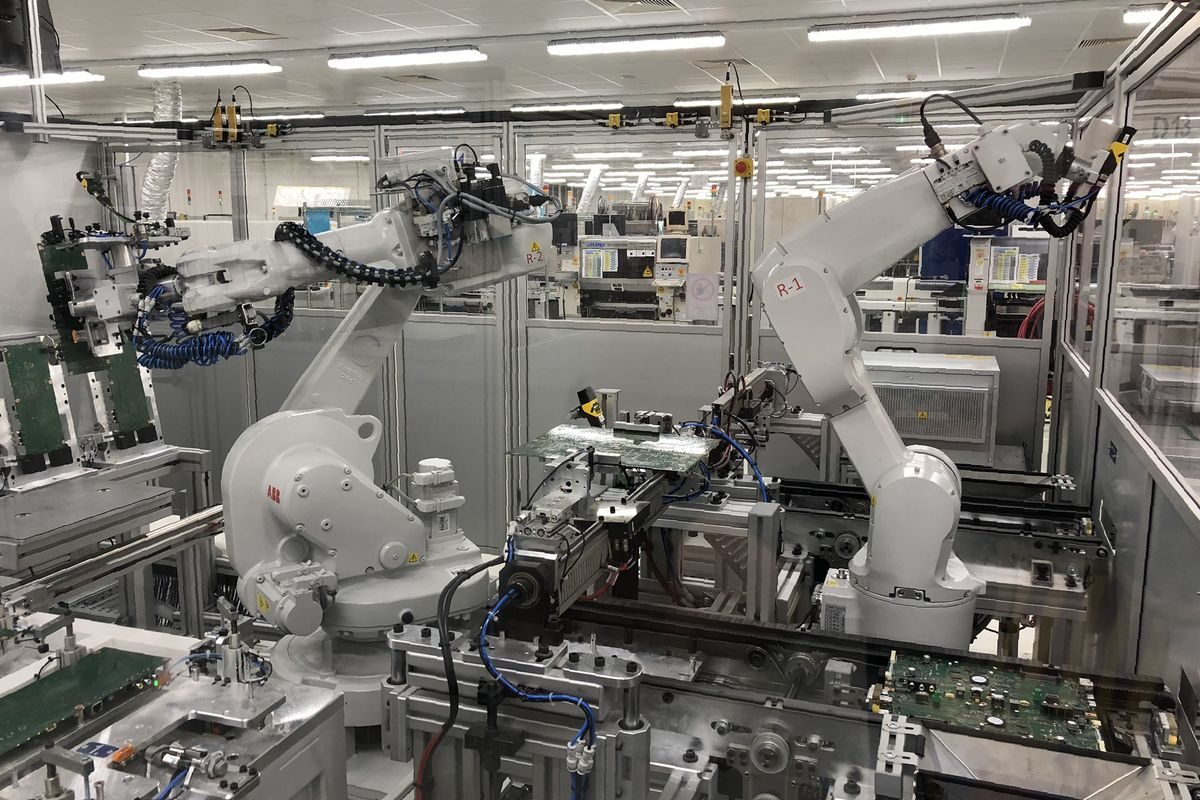

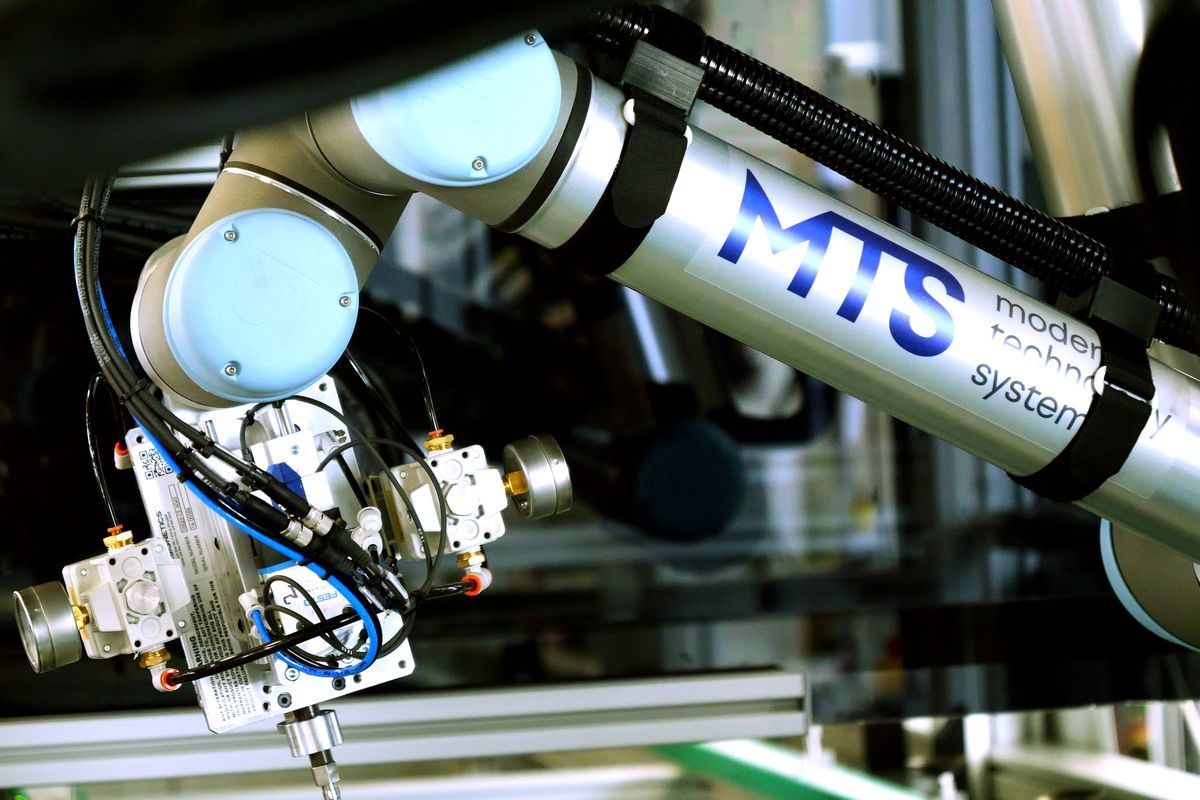

We help companies innovate production and logistics with intelligent technologies. We manufacture modern equipment from manual stations to fully automated robotic workplaces.

SERVICE – FAST AND HONEST

We build complete manufacturing lines and workstations from components that we distribute and can readily access. We perform repairs to ensure you won’t need to call us back.