We will help you choose and determine how to best deploy conveyors on your manufacturing line.

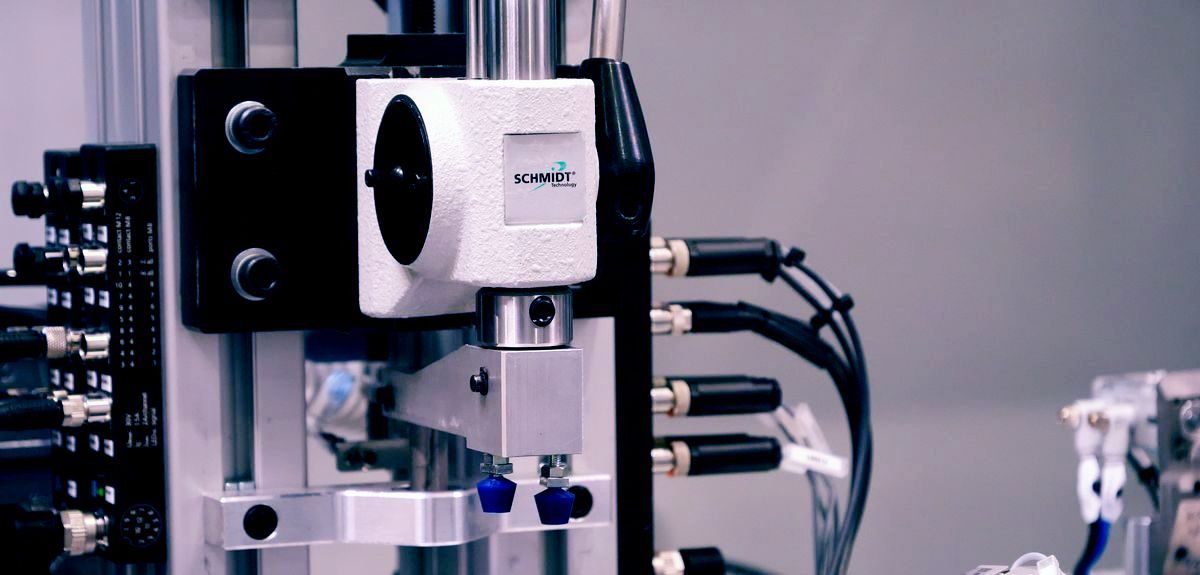

Presses and Press Equipment

Presses produce perfect parts that your operators would otherwise have to produce manually. We recommend manual presses, hydraulic presses and servo presses for various applications.

We believe that cheaper solutions may ultimately cost you more. This is why we deliver reliable presses from Schmidt. They are precise, rugged and will serve you well for years.

Contact us